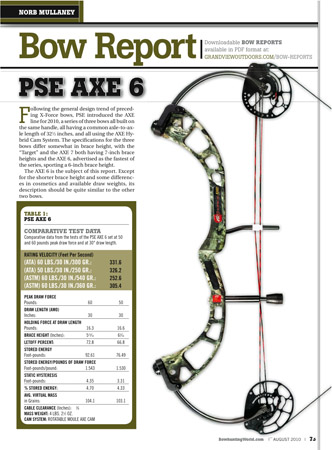

Following the general design trend of preceding X-Force bows, PSE introduced the AXE line for 2010, a series of three bows all built on the same handle, all having a common axle-to-axle length of 32 1/2 inches, and all using the AXE Hybrid Cam System. The specifications for the three bows differ somewhat in brace height, with the "Target" and the AXE 7 both having 7-inch brace heights and the AXE 6, advertised as the fastest of the series, sporting a 6-inch brace height.

Following the general design trend of preceding X-Force bows, PSE introduced the AXE line for 2010, a series of three bows all built on the same handle, all having a common axle-to-axle length of 32 1/2 inches, and all using the AXE Hybrid Cam System. The specifications for the three bows differ somewhat in brace height, with the "Target" and the AXE 7 both having 7-inch brace heights and the AXE 6, advertised as the fastest of the series, sporting a 6-inch brace height.

The AXE 6 is the subject of this report. Except for the shorter brace height and some differences in cosmetics and available draw weights, its description should be quite similar to the other two bows.

The handle is completely machined from structural aluminum alloy as are the limb pockets. The grip, in keeping with the low-torque philosophy, does away with the bulk of wooden or composite overlays in favor of using the structural metal of the handle to create both the front and back of the grip. Small elastomeric pads are inset in both sides to round out the cross section. The sight window offers a full 7 1/2 inches of usable length. It is cut 1/2 inch past center with an additional 1/4-inch clearance at the arrow pass. A single hole, tapped 5/16-24, is provided for mounting an arrow rest or plunger. It is centered 5/8 inch above the surface of the shelf and just aft of the pivot point of the grip. The limb pockets are pivoted at the extreme outer ends of the risers using a pair of socket-head cap screws to fasten the pocket to the riser.

The limb bolts pass through the base of each limb pocket and thread directly into the structure of the riser, avoiding the butts of the split-limb arrangement that is enclosed by an individual pocket structure that positions each limb unit. PSE calls this pocket design HyperSplit. The pockets support a pair of 12-inch-long, heavily preloaded limbs that are deflected beyond parallel when at rest. The limb elements carry a hole near the butt that fits over a projection in the limb pocket to anchor the element solidly in place. Each limb element is 3/4 inch wide, and the thickness tapers from the butt to the tip reinforcement. The reinforced tip is drilled to accept the axle.