Ross Archery CR334 Bow Report

*Download the Bow Report*

Ross Archery is a relatively new company that has launched a line of bows that gives every evidence that the company knows exactly what it is about and how to accomplish it. A look at the product line, which includes essentially four bows ranging in length from 28 to 37 inches, reveals a similarity in design and features that insists that “what is right for one is right for all.”

Ross Archery is a relatively new company that has launched a line of bows that gives every evidence that the company knows exactly what it is about and how to accomplish it. A look at the product line, which includes essentially four bows ranging in length from 28 to 37 inches, reveals a similarity in design and features that insists that “what is right for one is right for all.”

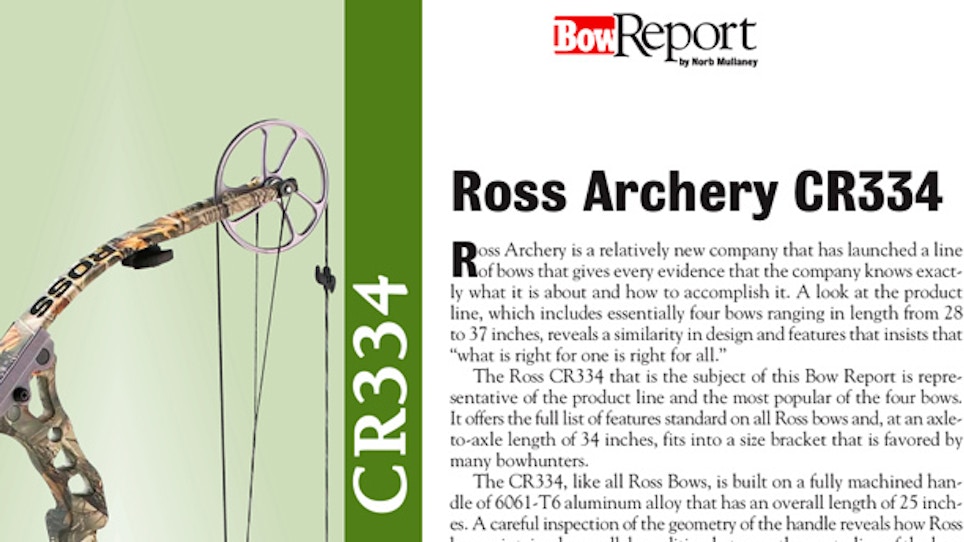

The Ross CR334 that is the subject of this Bow Report is representative of the product line and the most popular of the four bows. It offers the full list of features standard on all Ross bows and, at an axle-to-axle length of 34 inches, fits into a size bracket that is favored by many bowhunters.

The CR334, like all Ross Bows, is built on a fully machined handle of 6061-T6 aluminum alloy that has an overall length of 25 inches. A careful inspection of the geometry of the handle reveals how Ross has maintained a parallel condition between the centerline of the bow and the bowstring despite the natural eccentricity occasioned by the mandatory offset inherent in the three-track cam. The lower riser has a structural offset toward the string-hand side that is equivalent to the axial eccentricity of the cam. This causes the lower limb to be offset the same amount and thus, brings the string track into line with the centerline of the bow. I can’t remember seeing this done before in this manner. It does make the bow a true centershot design from a lateral perspective.The machining job is nicely finished with all nonfunctional corners well rounded. The small grip section is fitted with a slender laminated wooden pad on each side complete with a thumb rest for the bow hand. The arrow rest or cushion plunger area has two tapped holes (5/16-24 UNF) spaced 1/2-inch apart and centered 3/4-inch above the surface of the shelf. The standard AMO two-hole pattern for sight and bow quiver attachment is drilled and tapped (10-24 UNC) completely through the upper riser at the sight window. Two stainless steel bushings are set in the lower riser at the knuckle where the offset begins. The shelf is fitted with an upswept broadhead guard bolted to its outboard edge. *Read the rest of the report by downloading the PDF