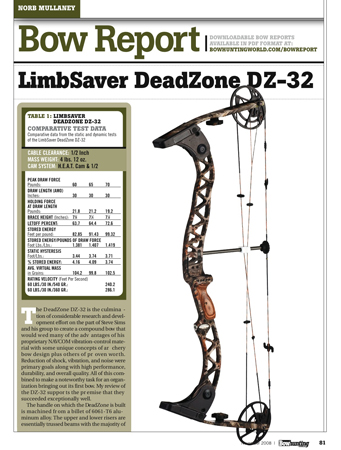

Limbsaver DeadZone DZ-32

*Download the Bow Report*

The DeadZone DZ-32 is the culmination of considerable research and development effort on the part of Steve Sims and his group to create a compound bow that would wed many of the advantages of his proprietary NAVCOM vibration-control material with some unique concepts of archery bow design plus others of proven worth. Reduction of shock, vibration, and noise were primary goals along with high performance, durability, and overall quality. All of this combined to make a noteworthy task for an organization bringing out its first bow. My review of the DZ-32 supports the premise that they succeeded exceptionally well.

The DeadZone DZ-32 is the culmination of considerable research and development effort on the part of Steve Sims and his group to create a compound bow that would wed many of the advantages of his proprietary NAVCOM vibration-control material with some unique concepts of archery bow design plus others of proven worth. Reduction of shock, vibration, and noise were primary goals along with high performance, durability, and overall quality. All of this combined to make a noteworthy task for an organization bringing out its first bow. My review of the DZ-32 supports the premise that they succeeded exceptionally well.

The handle on which the DeadZone is built is machined from a billet of 6061-T6 aluminum alloy. The upper and lower risers are essentially trussed beams with the majority of the connecting cross members featuring an I-shaped cross-section wherever functionality permitted. Lightening holes are added at the junctions of the cross struts and the tension and compression members to effect optimum weight reduction. The risers’ external corners are beveled with convex cuts that add eye appeal to the handle. The risers’ outer ends are held to the same thickness as the rest of the riser as they extend into the limb pockets and are sandwiched between the extended flanges of the pocket structure. There is a groove milled into the end of each riser to provide clearance for the limb adjustment bolt as it moves with respect to the riser when the draw weight is adjusted.

Measured from a straight line connecting the centerlines of the limb pivots, the DeadZone handle is reflexed about 15/8inches. The sight window has a usable length of o ver 9 inches and is cut past center 3/4inch. Two holes, tapped 5/16-24 UNF and spaced 1/2 inch apart, are provided for mounting a cushion plunger or arrow rest. These holes are centered 3/4inch above the shelf. The standard two-hole (tapped 10-24 UNC) pattern for attaching a sight or other accessory is incorporated in bosses on the cross struts on the upper riser. The shelf is drilled laterally with five blind holes for weight reduction. The add-on grip is a one-piece, sculptured section of laminated hardwood that slips in place from the rear and is secured by a through-bolt let into the outer surface. A stainless-steel bushing is threaded into the back of the lower riser just below the grip section to mount a stabilizer or other accessory. *Read the rest of the report by downloading the PDF