Alpine Silverado Match Grade Bow Report

*Download the Bow Report*

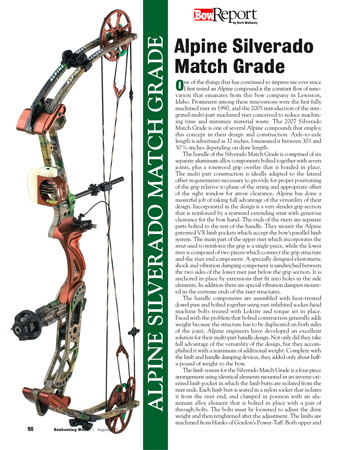

One of the things that has continued to impress me ever since I first tested an Alpine compound is the constant flow of innovation that emanates from this bow company in Lewiston, Idaho. Prominent among these innovations were the first fully machined riser in 1990, and the 2005 introduction of the integrated multi-part machined riser conceived to reduce machining time and minimize material waste. The 2007 Silverado Match Grade is one of several Alpine compounds that employ this concept in their design and construction. Axle-to-axle length is advertised as 32 inches. I measured it between 30 5/8 and 30 13/16-inches depending on draw length.

One of the things that has continued to impress me ever since I first tested an Alpine compound is the constant flow of innovation that emanates from this bow company in Lewiston, Idaho. Prominent among these innovations were the first fully machined riser in 1990, and the 2005 introduction of the integrated multi-part machined riser conceived to reduce machining time and minimize material waste. The 2007 Silverado Match Grade is one of several Alpine compounds that employ this concept in their design and construction. Axle-to-axle length is advertised as 32 inches. I measured it between 30 5/8 and 30 13/16-inches depending on draw length.

The handle of the Silverado Match Grade is comprised of six separate aluminum alloy components bolted together with seven joints, plus a rosewood grip overlay that is bonded in place. The multi part construction is ideally adapted to the lateral offset requirements necessary to provide for proper positioning of the grip relative to plane of the string and appropriate offset of the sight window for arrow clearance. Alpine has done a masterful job of taking full advantage of the versatility of their design. Incorporated in the design is a very slender grip section that is reinforced by a rearward extending strut with generous clearance for the bow hand. The ends of the risers are separate parts bolted to the rest of the handle. They mount the Alpine patented VX limb pockets which accept the bow’s parallel limb system. The main part of the upper riser which incorporates the strut used to reinforce the grip is a single piece, while the lower riser is composed of two pieces which connect the grip structure and the riser end component. A specially designed elastomeric shock and vibration damping component is sandwiched between the two sides of the lower riser just below the grip section. It is anchored in place by extensions that fit into holes in the side elements. In addition there are special vibration dampers mounted in the extreme ends of the riser structures. *Read the rest of the report by downloading the PDF