If you’ve killed every deer you’ve shot at with Remington Core-Lokt or Winchester Power-Point bullets, I’m not surprised. These aging softpoints still land where you aim them. They upset and penetrate reliably. But the Core-Lokt dates to the 1930s, and you probably don’t drive a 1930s automobile if you know what I’m saying.

Hunters have chased flatter bullet arcs and tighter groups since conical bullets replaced balls in muzzleloaders. Interest in long-range shooting has produced longer, sleeker missiles. Pointed polymer noses give bullets rocket-like profiles, boosting ballistic coefficients.

What’s ballistic coefficient? More hunters should ask, because BC is often twisted in print. It’s a number. Call it a convenient way to talk about drag — or measure a bullet’s ability to fight the forces that slow it down. BC doesn’t define drag. It comes pretty close if the bullet is similar in form to a “standard projectile.” The G1 standard looks like an early artillery round. The G7 standard better matches modern hunting bullets with long ogives (that radiused part of the bullet between tip and shank) and tapered heels (boat-tails). A high BC means the bullet fights drag valiantly, decelerating slowly. You get flat trajectory and high retained energy. That bullet also drifts less in wind than if it had a low BC.

But BC is a comparative measure, meaningless apart from the standard projectile. BC is commonly determined by reading velocity at two or three points 100 yards apart on a bullet path then calculating time of flight between them. “Unfortunately, not all BCs given by bullet makers are correct,” insists Dave Emary, Hornady’s chief ballistician. “Some are just optimistic estimates or bumped up by marketing departments to sell bullets. Others result from too few data points in short-range trials at velocities under 2,500 fps. BCs of long, sleek poly-tip bullets, driven fast, don’t hold up at distance.”

How does he know? Doppler told him — the same Doppler that helps us predict weather and nails us at 10 mph over the limit coming down a hill on the highway.

Like a laser rangefinder, a Doppler unit determines the position of a distant object — here a bullet — by reading a bounce. High-frequency microwaves record a Doppler shift in frequency reflected from the bullet. That shift reveals velocity, time of flight and distance traveled. Doppler devices vary a great deal in cost and capability. Those in military budgets bring taxpayers to their knees, to defend their liberties. Hornady Manufacturing recently bought a more modest but still robust Doppler unit. It resembles a white porcelain plate the size of an oven door. A horizontal split divides the top (sending) unit from the bottom (receiver). This unit registers bullet location every 2 feet to ranges approaching a mile. A resulting graph shows the drag component of bullet flight.

With Doppler, Hornady has developed hunting bullets you’ll want to consider if you shoot long. The series is called ELD-X (Extremely Low Drag, Expanding). There’s also an ELD-Match series.

Time for a hunting tale? OK. I used one of the first ELD-X bullets to take game abroad. In grass-flattening, wind-driving horizontal rain off the Scottish coast, I waded an icy creek in hiking shoes, hopped like a chimp to stay below waist-high heather then bellied to a hilltop. Sleet in my teeth, I gave the Leica scope a quick wipe and steadied the Sauer 404, a .300 Winchester. At the shot a fine red stag collapsed, 90 yards off. A proper shot, but hardly a test for a bullet with much longer legs.

The testing had already happened. Doppler showed Emary — and colleagues Joe Thielen, Jayden Quinlan and Ryan Damman — slight irregularities in the deceleration curves of fast bullets. The unlikely explanation: change in bullet shape during flight! How could that be? “The poly tips were melting,” Dave says. “Friction-induced temperatures run to 800 degrees. BC is largely a function of bullet shape. Though a tip accounts for less than 1 percent of bullet weight, a deformed tip reduces BC. Trajectory gets steeper. Of course, accuracy deteriorates, too.”

You’ll remind me now that hollowpoint boat-tail bullets favored in 1,000-yard matches, and used at distance by deer hunters don’t melt. “But hollowpoint noses don’t finish up uniformly,” counters Joe Thielen. “Forming the nose leaves irregularities. With poly-tips, every meplat (nose profile) is identical.”

Are polymer-tip bullets just hollowpoints with a cap? “No,” insists Joe. “Hunting-bullet cores work with the tip during upset. The cavity is proportioned to cause the rate and degree of expansion desired. After expansion begins, tip shape, material and disposition don’t matter.”

By the way, Hornady’s ELD-X team denounces the use of match bullets on deer. “OTM, or open-tip match bullets, produce erratic tracks in gelatin,” says Jayden Quinlan. “Expansion and penetration are unreliable. Tips can collapse inward to cancel upset; or they shear, causing the shank to tumble and yaw.”

As deer hunters know, Hornady developed pliable, resilient bullet tips for lever-rifle cartridges, so pointed bullets could be stacked nose-to-primer safely in tube magazines. LeverEvolution ammo and FTX bullets remain hugely popular. But the ELD-X project sent Emary’s team in the opposite direction, to find hard-tip material that wouldn’t melt during sustained aerodynamic heating. The resulting Heat Shield Tip has a glass transition temp (point at which hard material turns rubbery) of 475 degrees, eight times as high as that of nylon and Delrin tips! Its melt temperature of 700 degrees is twice as high, and ensures that any tip melt will be insignificant.

Loaded, and in profile, ELD-X bullets are indistinguishable from other sleek Hornadys, until you examine the tip. It’s a darker red than other Hornady poly tips, and translucent. A tad larger than SST tips, and with a bigger shank, it’s fitted to a lead-core bullet in a nose cavity coned at the bottom. The ELD-X has a tapered jacket with an Interlock “pinch” well up on the shank. “It protects more shank than does the lower band on Interlock bullets,” says Dave. Jacket taper and the generous tip cavity up front trigger upset at impact speeds as low as 1,600 fps. But the jacket base is thick, to prevent shattering and ensure enough weight for pass-through penetration after 2,900-fps impact.

“Though ELD-X trials have given us kills to 865 yards, we’re not recommending long shots at game,” emphasizes Dave, who often uses iron-sighted lever rifles afield. “The ELD-X is simply a step in bullet development. It delivers superior accuracy and flatter arcs at distance, with lethal upset and penetration over a wide range of impact speeds. In gelatin, it drives straighter than do hollowpoints. It’s very versatile, designed as much for elk as for whitetails. It’s the only bullet you’ll need in a high-performance cartridge, up close or far away.”

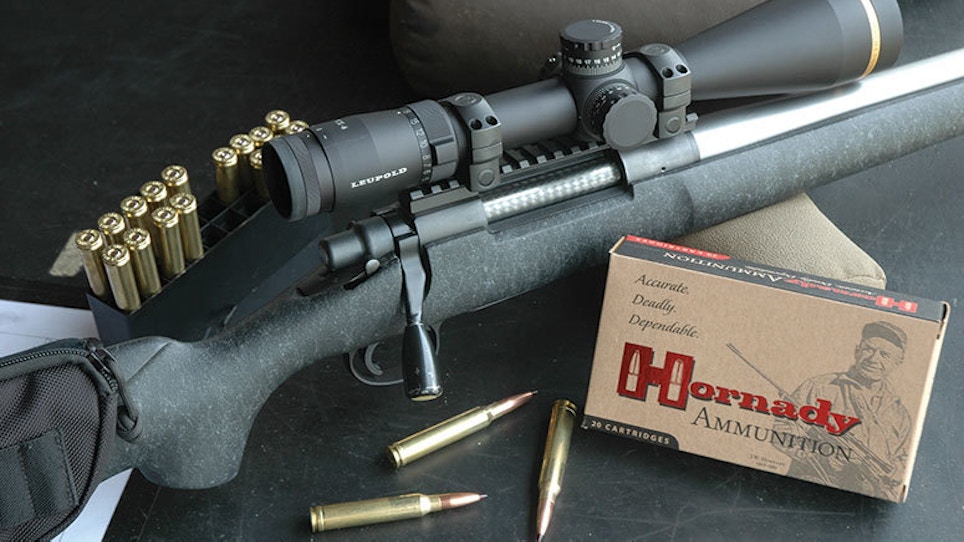

I first fired ELD-X bullets in Nebraska, a couple of hours’ drive from Hornady’s factory. Targets were steel plates, spaced from 300 to 1,200 yards. “Don’t bother with any closer than 600,” Dave told me. He uncased a custom-barreled Remington 700 in .300 Winchester, topped with a Leupold VX-6. “Have at it.” And I did. Dead air early on made hitting easy out to 1,000 yards. When the breeze picked up, Dave’s wind calls adjusted mine. A sloppy cheek weld sent some bullet awry, but I could lay no miss to the rifle or the 200-grain bullets. I quit with a center hit at 1,200 steps.

Back at the lab, we sent those .30-bore ELD-X bullets into gelatin blocks. At 150-yard velocities, big temporal cavities reached from 2 to 11 inches, the 23-inch paths tapering to bullet diameter 18 inches in. Temporal-cavity diameter wasn’t quite as great at 800-yard velocities, but straight-line penetration ran to 24 inches. Recovered bullets mirrored reaction from the gelatin, close-range impact producing broader mushrooms at the expense of a little weight.

How does the ELD-X compare with competing poly-tip bullets in gelatin? A hollowpoint at 150-yard impact speed opened a wide but short temporal cavity from 5 to 13 inches in, stopping at 16 inches. Two others drove deeper; but one cut a banana path. At 800-yard velocities, wound channels of the three “other” bullets were notably shorter and slimmer. Two of those bullets strayed off course.

Hornady has introduced ELD-X bullets in its ammunition as Precision Hunter loads, with single-base, temperature-insensitive powders and velocities matching those of the company’s Custom line. At this writing, Superformance loads do not feature ELD-X bullets. A 175-grain 7mm and a 212-grain .308 ELD-X are slated for sale as components to handloaders.

I’m told other ELD-X bullets will appear later, and that the Precision Hunter ammunition stable will grow. “But we’ve no plans to make ELD-X bullets in diameters smaller than 6.5mm,” says Ryan Damman. “The Heat Shield Tip offers little if any advantage until G1 BCs exceed .550. A 6mm bullet with that BC would be exceedingly long, impractical in most commercial cartridges and popular rifles.” Neither is the ELD-X likely to appear in large diameters. You don’t need long-range precision or a flat arc to brake a mud-caked buffalo bent on mayhem.

Given their sophistication and the cost of their Doppler-based development, you might expect ELD-X bullets with Heat Shield Tips to carry a fat tariff. But Precision Hunter ammunition lists for about the same price as Superformance with SST bullets. Handloaders will pay considerably less for ELD-Xs than for flagship hunting bullets from some other premium bullet makers.