Building your own rifle is one of those ultimate do-it-yourself projects right up there with building a kit car. Back East, it was hard to find an avid hunter who hadn’t at least put together a muzzleloader kit at some point. Building custom or just knock-about hunting rifles from surplus military rifles has been going on since there were surplus rifles.

The progression to DIY modern sporting rifles (MSR) was not only natural, but also logical because of the inherent modularity of the design. An entire industry exists around the various stocks, handguards, grips and other doo-dads you can attach with minimal effort or skill. And while it’s possible to construct an entire modern sporting rifle on your own by assembling various purchased components, you end up with a rifle that was merely assembled. In the words of the “world’s greatest gun salesman” — “You didn’t ‘build’ that.”

According to ATF, “Firearms may be lawfully made by persons who do not hold a manufacturer’s license under the GCA provided they are not for sale or distribution and the maker is not prohibited from receiving or possessing firearms.”

With that understanding, shooters with machining skills started machining their own MSR lower receivers. Manufacturers also began offering lowers in various stages of completion to make them easier to finish while stopping short of creating what ATF defines as a “firearm” that needs a serial number and FFL to transfer. The so-called 80-percent-finished receivers are the most popular of those and I recently received a “Buy Build Shoot” (BBS) kit from Polymer80 to see what all is involved. “The kit is ideally configured to allow the customer to quickly acquire an AR-15 or .308 rifle in various configurations to build their own gun, and then go out and test it in the field right away,” says Polymer80 co-founder David Borges.

Previously, I had built muzzleloader kits, sporterized several Mausers and even made a tiny kid-size 28-gauge side-by-side shotgun. So I am familiar with building guns, but an MSR was new territory to me. If you’re not familiar with how one works, the idea of building an MSR can seem intimidating. There are a lot more parts and it isn’t as intuitive as a two-lug bolt-action rifle in a wood stock. Now that I’ve built this kit, however, I can say there’s nothing to be intimidated about and building it provides a much better understanding of how MSRs work.

The Polymer80 BBS includes everything you need to build a complete rifle except for a drill press, hand drill and X-Y-axis vise that you need to finish machining the polymer lower receiver. Borges says he finds “a lot of our customers are guys who are new to the gun build space, but have always wanted to try.” Reasoning that the average do-it-yourselfer doesn’t have a fully equipped machine shop, I went out and bought an inexpensive 10-inch drill press from the local big box hardware store and an X-Y-axis vise from Harbor Freight for this project.

All of the proper drilling and machining bits are included in the kit, and the 80-percent receiver comes with a jig so you make the right cuts and holes in the right places. Polymer80’s website has links to very clear instruction including video.

Machining is as simple as putting the lower in the jig, leveling and clamping it in the vise, setting the depth of your drill press and drilling a succession of holes followed by cleaning up the holes by feeding the lower along the milling bit using the vise. “On the AR frame, there are some tight areas you need to be watchful of while milling,” cautions Borges. “The Mil-Spec calls for very tight tolerances in the fire control pocket, right next to where the pistol grip detent hole is presenting itself up through the safety selector hole on the right side of the frame.”

The Polymer80 project was enjoyable for the author and his son. It was also an opportunity to learn and explain the workings of an MSR.

Bottom line: if you can drill a hole, stop on a line and turn a crank, you can do this project. My son and I had the milling done in an hour — and that’s with stopping to take photos. The only difficulty we ran into was we didn’t initially machine the firing control pocket deeply enough. That made the tail of the trigger sit too high for the safety lever to install. The mill bit has a depth line scored on it indicating how deeply to mill the pocket and we conservatively stopped at the bottom edge of that line. Simply milling to the top of the line and “chasing” that last millimeter of depth was all it took for all of the parts from the supplied lower receiver kit to fit and function flawlessly.

As for the upper, it was equally easy to assemble. We did it using nothing more than needle nose pliers, a pin punch, hammer, Allen wrench set and a large adjustable wrench. The bolt-carrier group conveniently came pre-assembled.

Before starting this project, one of the areas that concerned me was barrel attachment because the normal delta ring and barrel nut require special tools. According to Borges, Polymer80 tries to “stick to barrel nuts that make it easier on the end user for assembly and disassembly.” The kit comes with a barrel nut you can tighten using a large adjustable wrench. Normally on this rifle design, you also have to align a hole in the barrel nut with the gas tube port in the front of the upper receiver for the gas tube to pass through. However, the BBS barrel nut is smaller in diameter and the gas tube passes over, not through it.

I initially assembled everything only hand tight to make sure it all fit properly before taking the BBS apart so I could give it a more “finished” look using Brownell’s ALUMA-HYDE II. The only part that doesn’t come off easily is the bolt catch because the pin that holds it seats deeply in the polymer receiver and can’t be driven out from the other side.

A light surface scuffing and two light coats of ALUMA-HYDE II later, I reassembled the BBS tightening everything to the proper torque and topped it with a Burris 3-9x40mm Predator Quest scope for final function and accuracy testing. Whenever I work on a semi-auto, there’s a function regimen I go through. First, I check that the safety works and that the hammer stays cocked when the bolt closes. Next, I load a single round in a magazine and fire it to make sure the gun feeds, ejects and the bolt locks back. Finally, I load only two rounds in a magazine and fire them to make sure the semi-auto functions properly. The BBS functioned fine.

A light surface scuffing and two light coats of ALUMA-HYDE II later, I reassembled the BBS tightening everything to the proper torque and topped it with a Burris 3-9x40mm Predator Quest scope for final function and accuracy testing. Whenever I work on a semi-auto, there’s a function regimen I go through. First, I check that the safety works and that the hammer stays cocked when the bolt closes. Next, I load a single round in a magazine and fire it to make sure the gun feeds, ejects and the bolt locks back. Finally, I load only two rounds in a magazine and fire them to make sure the semi-auto functions properly. The BBS functioned fine.

“The gun just shoots’ is a common response we get once customers finish and get it tested in the field,” says Borges. That was my experience, too. The BBS averaged 1.2-inch groups at 100 yards with Black Hills 60-grain softpoint loads. The tightest group was 0.9 inch using Black Hills 50-grain V-Max loads. There were no malfunctions of any kind. Overall, the gun exceeded my expectations, especially regarding accuracy, considering it has a rack-grade barrel and a trigger that broke at 8½ pounds pull.

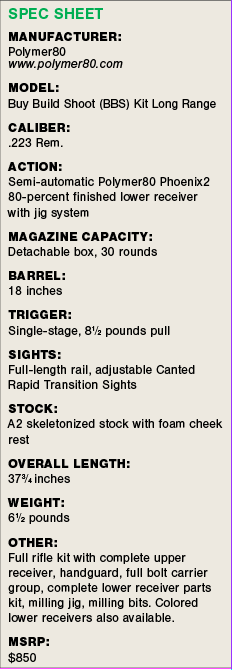

The specific model here is the Long Range that Borges calls a “lightweight solution that is configured to reach out and touch critters.” It tips the scales at a feathery 6½ pounds and with its slim keymod forend points quickly and easily. Currently, Polymer80 offers a least a dozen different types of Buy, Build, Shoot kits ranging from AR pistols to .308 rifles. Many of the component parts are outsourced, so you can expect variations between models and even within the same model over time. All are backed by a lifetime warranty.

“We’re talking about folks who want to get the experience of building their own rifle. For those people who love to coyote hunt or varmint hunt using .223/5.56 rounds, this is going to be a fantastic option,” says Borges. “Within a few hours you’ve got a gun that you can be proud of because you built it in your own shop, and it’s going to be a fun and memorable experience.”