Pine Ridge Archery began with an airplane propeller and a fish hook. Confused? Let me explain. Actually, back in the ‘50s, inventor Dewey Broberg was immersed in his own hobbies when he unexpectedly began to grow a corporation. It is the perfect archery business story and yet archery was the last business to come into the Du-Bro Products fold (see www.dubro.com) and then only because Jim, Dewey’s son, was an avid bowhunter.

Pine Ridge Archery began with an airplane propeller and a fish hook. Confused? Let me explain. Actually, back in the ‘50s, inventor Dewey Broberg was immersed in his own hobbies when he unexpectedly began to grow a corporation. It is the perfect archery business story and yet archery was the last business to come into the Du-Bro Products fold (see www.dubro.com) and then only because Jim, Dewey’s son, was an avid bowhunter.

Today Du-Bro—still a family-owned business—is a significant player in the hobby industry with more than 1,200 items offered in the three industries it services: fishing, hobby modeling, and archery—and Pine Ridge Archery is growing fast, having placed an incredible 250 new SKUs in its inventory for 2012. Jim Broberg is the current president; sisters Gail and Kathy are involved in human resources and finance; and Dewey, now retired, continues to drop by the office.

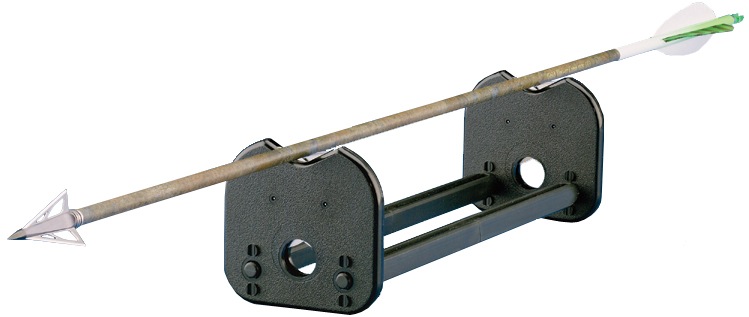

Applied to archery, Dewey’s very first invention became Pine Ridge’s initial product—40 years later in 1997. This item is still available and sells steadily because it serves a continuing need, says Brian Bychowski, advertising and marketing director. It is, of course, the venerable Arrow Inspector ($33).

The Arrow Inspector looks simple, but looks can be deceiving. It is a precision instrument designed to help insure smooth, accurate arrow flight. “If your arrows don’t spin true, they won’t fly true,” Bychowski says, “and when shooting today’s ultra-fast bows, small misalignments can result in disaster. The same principle governs airplane propellers, where a tiny weight or balance differential can shake an airframe to pieces.”

An alignment checking device helps model hobbyists balance propellers and helps bowhunters balance arrows. The Arrow Inspector gives an immediate visual indication of misalignment with shafts or components—nocks, heads (blades or ferrules) and inserts, as well as vane balance. “It works as well for carbon as for aluminum arrows, too,” says Bychowski.

The Arrow Inspector uses low friction, machine-cut steel axles and precision cut aluminum wheels to detect minute deviations in an unbalanced arrow. It’s ideal for hunters, target and 3-D shooters, and archers who fletch their own arrows. After all, just shooting a tight pattern and pulling the arrows from a target can bend shafts causing them to fly erratically. Not only will they not fly perfectly straight, but a percentage of the energy they carry will dissipate in flight and hitting the target at even a slight angle reduces penetration. A quick spin on The Arrow Inspector lets you know if you can trust that arrow again for straight, accurate shooting.

See page 2 for more.

Bychowski feels it is important for the industry to understand that all Pine Ridge products are invented and manufactured—not just assembled and packaged—in its factory in Illinois. And 2012 has been a break-out year with phenomenally rapid growth.

Bychowski feels it is important for the industry to understand that all Pine Ridge products are invented and manufactured—not just assembled and packaged—in its factory in Illinois. And 2012 has been a break-out year with phenomenally rapid growth.

“This year Pine Ridge added more than 250 SKUs,” Bychowski says, “but we didn’t just go to China to import a bunch of new stuff. We’re an American injection molding company and we can operate 24/7 with the presses in our own factory. We have our own screw machines, foam-, rotational- and blow-molding machines, and our own in-house printing press to do packaging. We have video production and in-house sales and service. We try to do everything under this roof. So when we added 250 SKUs we did it here, with manufacturing and marketing expertise, not by importing.”

By 2011 Pine Ridge had grown to the point that the principals needed to develop a road map for the future. “We felt the proper direction was similar to Du-Bro in the modeling industry,” Bychowski says. “After many years of slowly building the line, adding a product here and a product there—treestand accessories, for instance—we decided to look at the industry from the archery dealer’s perspective. We asked, ‘What does an archery dealer need to sell? What do they sell most of and what will they always need to continue selling?’

“We decided to return to the Du-Bro philosophy of ‘being the non-glamorous, nuts-and-bolts supplier for the dealer.’ Du-Bro is that way for hobby shops. Check any hobby shop in the world and they have three walls filled with Du-Bro products. We wanted to move Pine Ridge in that direction, so that when a dealer says he needs something basic but crucial, he calls Pine Ridge.

“And that’s partly why we had such a big product launch this year. A great number of our new SKUs are color and quantity variations. Colors are so hot right now we have most items available in 8-9 colors and different quantities and configurations. The SKUs added up fast.”

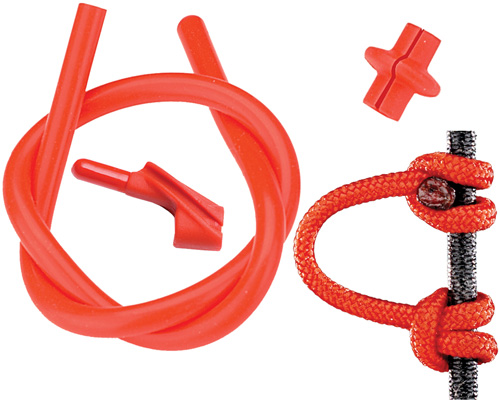

An example of Pine Ridge’s 2012 introduction and its plunge into the bottomless stock keeping units of flashy colors and useful combinations is the $14 Archer’s Combo Pack (a ¼-inch Nitro Peep with two pieces of matching silicone tubing, a 5-inch Nitro string loop, and soft, slotted kisser button with clamps). All items are color-matched and the pack is available in 8 colors.

“If there is one thing I could stress,” says Bychowski, “it is that we are positioning Pine Ridge to serve the needs of America’s archery dealers. If in any way we’re not doing that now or in the future, they can call me.”

“If there is one thing I could stress,” says Bychowski, “it is that we are positioning Pine Ridge to serve the needs of America’s archery dealers. If in any way we’re not doing that now or in the future, they can call me.”

Pine Ridge Archery Products, a division of Du-Bro Products—located at P.O. Box 310, 480 Bonner Road, Wauconda, IL 60084—can be contacted by phone at (877) 746-7434 or (847) 526-2349. You can begin an Internet search at their home page www.pineridgearchery.com. A number of Pine Ridge videos are posted to YouTube.com and they maintain active Facebook.com and Twitter accounts.